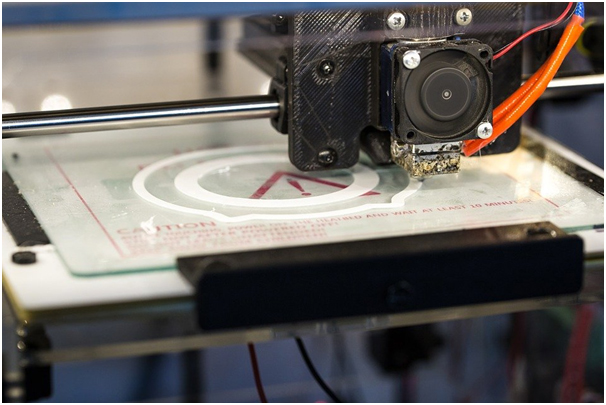

Whilst a still relatively new and rapidly growing industry, 3D printing has shown just how flexible it is in terms of different types of projects that have been undertaken and larger scale plans too. Some of the more complex and interesting designs undertaken with exciting 3D printing in Dubai projects by Generation 3D have shown how high the potential is becoming.

When it comes to 3D printing, though, what are some of the big benefits that are seeing it more widely used across a wide number of industries, and what are some of the drawbacks that could hamstring the progress moving forward?

Rapid Prototyping

On a larger scale, 3D printing can be done very quickly, oftentimes within a matter of hours which means prototyping designs can be done very quickly. It’s an inexpensive process and modifications can be made very quickly with a deft hand and have become very useful for prototyping.

Strong and lightweight

Plastic is the most common material for 3D printing, and that means 3D printed items are typically very strong and very lightweight as well as the ability to be produced from materials that are heat resistant, higher in strength, and many other features too. 3D printed materials are widely used in elite-level motorsports like F1 which is all the testament needed to how strong and how lightweight these pieces can be.

Environmentally Friendly

With a reduction in the amount of material wastage and using different materials, 3D printing is being credited as a more environmentally friendly manufacturing approach. It is looking to be used as an alternative to buildings too with trials for 3D printing homes in the middle east, another step to reduce wastage and use different materials.

With the good, there are some drawbacks that come with 3D printing too as limiting factors.

Limited build size

3D print chambers can be quite small, when it comes to printing larger designs they often need to be smaller pieces that are joined together. There are some solutions being made for this, but they’re still a long way from being more mainstream, and as such restricted build size needs to be considered.

Structure and weakness

Whilst one of the big strengths attributed to 3D printing is the strength of the designs that are made, there are instances where delamination can happen under certain stresses or orientations. Different forms of 3D printing such as fused deposition modeling (FDM) can enhance these weaknesses further and need to be considered when choosing a print type.

3D printing is still a young and growing industry so there are lots of changes to come from to both things that are considered pros of the industry and things that could be considered drawbacks too, but for now things are certainly looking very positive for the 3D printing space and there’s a lot of positives to come with this manufacturing process.