The consortium led by Rolls-Royce, which is creating a compact nuclear power station known as a small modular reactor (SMR), has revealed its latest design and an increase in power as it completes its first development phase on time and under budget. It also announced that it is aiming to be the first design to be assessed by UK regulators in the second half of 2021, which will keep it on track to complete its first unit in the early 2030s and build up to 10 by 2035.

Patrick Regis, Rolls-Royce’s CEO for the Middle East and North Africa region, explained that this is especially relevant for countries looking to accelerate their power generation output with low carbon energy. He said: “SMRs represent an ideal solution to meet the growing electricity demands in countries throughout the Gulf area, especially those focusing on sustainable sources of power like the UAE and Saudi Arabia. The population of the GCC has grown fourfold in its 40 years and with that, so too has the demand for power.”

As the power station’s design has evolved and improved, with more than 200 major engineering decisions made during this latest phase, the team has optimised the configuration, efficiency and performance criteria resulting in an expected increased power capacity, without additional cost, from 440 megawatts (MW) to 470MW.

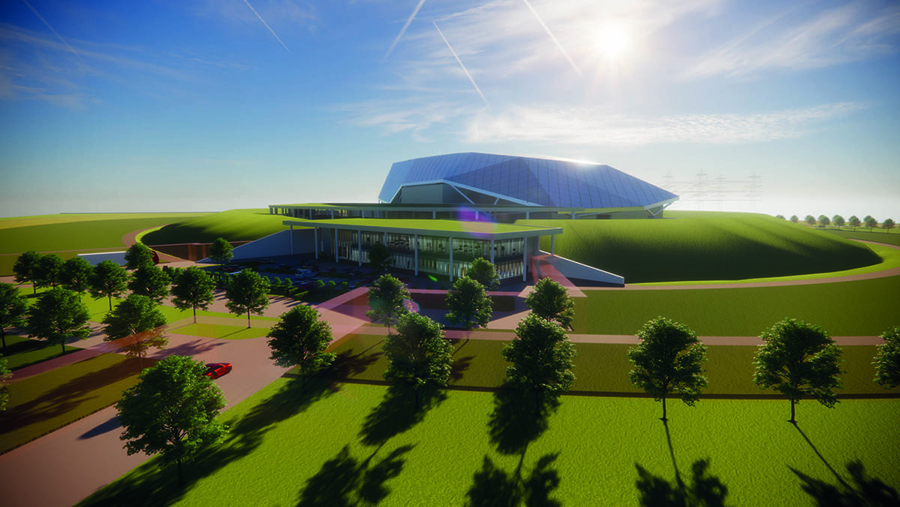

The refreshed design features a faceted aesthetic roof with an embankment surrounding the power station to integrate with the surrounding landscape and a more compact building footprint, thanks to successes optimising the use of floor space.

Tom Samson, Chief Executive Officer of the UK SMR consortium, said: “Nuclear power is central to tackling climate change, securing economic recovery and strengthening energy security. To do this it must be affordable, reliable and investable.The way we manufacture and assemble our power station brings down its cost to be comparable with offshore wind at around £50 per megawatt-hour. As we reach the end of our first phase, I’m proud that our team has designed a product that can be commoditised to provide the scale required to be a key part of the world’s decarbonisation efforts.”

The power station’s design cuts costs by using standard nuclear energy technology used in 400 reactors around the world, so no prototyping is required. The components for the power station are manufactured in modules in factories, before being transported for rapid assembly inside a weatherproof canopy. This replicates factory conditions for precision activities and further cuts costs by avoiding weather disruptions. The whole sequence secures efficiency savings by using streamlined and standardised processes for manufacturing and assembly, with 90% of activities carried out in factory conditions, helping maintain extremely high quality. In addition, all spoil excavated will be reused on site to build the embankment, removing the need for it to taken off site.